Wrapping a Motorcycle: More Than Just Aesthetics

Many people’s first reaction upon hearing about wrapping a motorcycle is that it’s just about changing colors, adding designs, and expressing individuality. However, after truly understanding the industry, they realize that the value of wrapping goes far beyond appearance. It has very practical significance in terms of paint protection, flexibility of use, and long-term maintenance.

Compared to traditional painting, one of the biggest advantages of wrapping a motorcycle is that it’s removable. This may seem insignificant, but it’s crucial for many riders, customization shops, and brands, because it means personalized designs can be applied without damaging the original paint.

Contents

The Complex Curves of Two-Wheelers

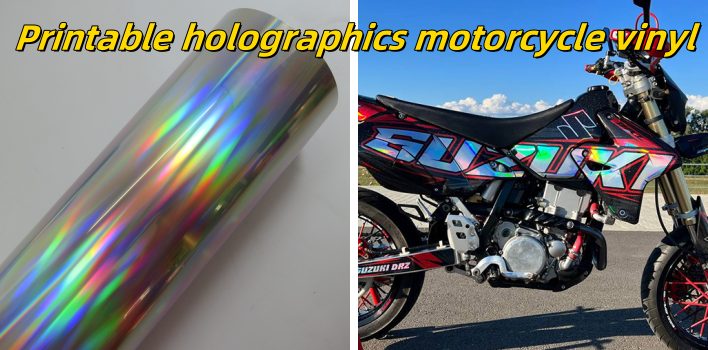

The surface structure of a motorcycle is far more complex than that of a car. The fuel tank, fairings, side panels, and tail sections are smaller in area, with more concentrated curves, and are constantly subjected to high temperatures and vibrations during use.

This requires the wrapping material to have good stretchability in all directions, not just for flat surfaces. Some thin vinyl materials that seem “sufficient” often cause problems when actually wrapping a motorcycle, such as edge shrinkage, noticeable surface stress marks, and even delamination and peeling.

Paint Protection is Often Underestimated

Many riders only truly appreciate the paint protection benefits of wrapping a motorcycle after using it for a while. During daily riding, flying stones, dust friction, fuel spills, UV radiation, and frequent washing gradually damage the original paint.

Wrapping a motorcycle provides a buffer layer for the paint. Minor scratches will only remain on the surface of the wrap, without directly damaging the base coat. When it’s time to change the style or remove the wrap, as long as the material and installation are done correctly, the original paint usually remains in good condition.

Material Stability is Important for Professional Installers

For professional installers, material stability directly affects installation efficiency. If the wrap shrinks unevenly when heated, doesn’t stretch smoothly, or requires repeated scraping and pressing to conform to curved surfaces, the installation time will be significantly extended.

Unstable materials are not only time-consuming but also increase the risk of rework. Therefore, customization shops and brands that truly value quality often prioritize a mature adhesive system and stable polymer structure, rather than just focusing on whether the pattern is “flashy enough.” Applications are constantly expanding.

Design trends may change, but the demand for high-performance materials remains constant. More and more distributors, installers, and brands are realizing that reliable performance standards and batch consistency are equally important in the wrapping a motorcycle industry.

Today, wrapping a motorcycle is no longer just about aesthetics; it is a mature solution that combines beauty, protection, and flexibility.

Choosing the Right Wrap Material

The key to long-term use always lies in the material itself. Just as you wouldn’t use household paint to spray a motorcycle, you shouldn’t choose low-grade wrap materials that will age and peel off after only a few months.

At Great K2, we specialize in the research, development, and manufacturing of raw materials for wrapping a motorcycle. Our wrap materials are designed for complex curves and long-term outdoor use, offering flexibility, stability, and weather resistance, maintaining consistent performance across different application scenarios. For professional customers who want to strike a balance between installation efficiency and final results, the material itself is the most important factor.