Understanding the Cost Factors of Rigid-Flex PCB Manufacturing

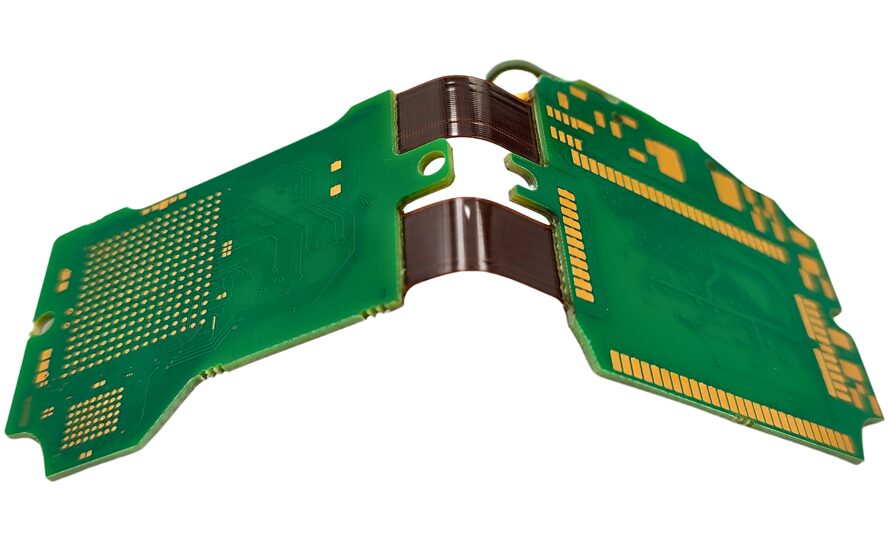

Rigid-Flex Printed Circuit Boards (PCBs) have revolutionized the electronics industry with their unique combination of flexibility and rigidity which makes them ideal for applications of space optimization and durability. Nevertheless, the process of their manufacturing is still quite complex which increases their overall cost.

In this essay, we will go through the complexities of these cost concerns, providing valuable insights for manufacturers and stakeholders to understand the nuances of rigid-flex PCB production.

Contents

The Main Factors that Affect Rigid-flex PCB Price

Firstly, we will talk about the main factors which will affect the prices for rigid flex PCBs, such as materials, PCB dimensions, trace width and spacing, surface finishes, number of layers, thickness, applications and special requirements., etc.

- Material Choice

Rigid-flex PCB manufacturing mainly depends on the type of material you select. This significantly impacts the board’s performance and cost like that of rigid-flex PCB which is made up of materials like flexible epoxy laminate, FR-4, and fiberglass laminate are commonly used because of their ability to strike a balance between flexibility and strength. Other mechanical properties such as flexural strength, bending strength, and shear strength also play a key role in determining the material’s suitability for rigid flex PCB applications. Other aspects that influence the functioning of materials such as rigid-flex PCB include the thickness of the board, factors like Raman scattering, infrared radiation, and coupling that affect the overall signal quality. Heat transfer capabilities are crucial, and the material must exhibit good thermal conduction to dissipate heat effectively. Additionally, applications often demand circuit boards that can withstand a wide range of temperatures, from -40°C to +140°C.

- Dimensions for Optimal Performance

The physical dimensions of the PCB also influence the manufacturing process and, consequently, their overall cost. For instance, common sizes of PCB are 21 x 24”, 18 x 21”, and 18 x 24” which are standard dimensions. However, tailoring the size to specific requirements, such as rigid-flex PCB can lead to cost savings by optimizing material usage. Smaller-sized boards contribute to reduced material consumption and facilitate a more manageable manufacturing process.

- Number of Layers

Rigid-flex PCBs are composed of multiple layers of flexible and rigid materials bonded together to achieve the desired balance of flexibility and strength. The number of layers directly influences the manufacturing cost as each layer adds complexity to the production process. The right balance between flexibility and functionality requires careful consideration of the number of layers used in PCB. The number of layers, specified by terms like rigid-flex PCB introduces considerations related to manufacturing complexity and cost structures.

- Surface Treatment

The finishing processes applied to rigid-flex PCBs significantly impact their final properties and, consequently, the overall cost. Common finishing processes include etching, encapsulation, electroless plating, decoupling, and immersion gold. The surface finish not only protects the board but also influences its electrical properties. Selecting appropriate finishes, such as rigid-flex PCB requires a nuanced understanding of the application’s demands and the desired performance characteristics.

- Size of Hole

The size of holes in rigid-flex PCBs is another critical aspect influencing their manufacturing process. Various methods such as laser cutting, hole drilling, and manual hole-making enhance the complexity and cost of manufacturing. The choice of hole size is dictated by factors such as the type of drilling method employed and the intended components that need to pass through the holes. Design considerations related to rigid-flex PCB involve precision in specifying hole sizes. Manual hole-making is a common practice, and manufacturers must allocate sufficient time to ensure accurate hole placement and dimensions.

- Trace Width and Spacing

Trace and space dimensions in rigid-flex PCBs are also critical for ensuring signal continuity and preventing undesirable effects like ghosting. Trace width, signal width, minimum trace space, and clearance all influence the overall flexibility and functionality of the PCB. Design considerations involve optimizing these dimensions based on specific requirements, such as rigid-flex PCB manufacturers.

- Aspect Ratio and Thickness of PCB

The aspect ratio of rigid flex PCBs, determined by the length divided by the width, is necessary for achieving the desired balance between flexibility and rigidity. It is influenced by board thickness which affects overall rigidity. Measurement tools such as gauges and rulers help in maintaining the thickness of design specifications. While a standard thickness of around 3.2 mils to 3.4 mils is common, customization based on specific requirements, such as rigid-flex PCB manufacturers, introduces considerations related to manufacturing cost and process.

- Tailoring to Application Requirements

The cost of the rigid-flex PCBs also depends upon unique specifications and requirements incorporated. Components such as connectors, power, ground, voltage dividers, and signal elements, resistors, inductors, capacitors, and varistors, can be incorporated based on the application’s demands. The selection of components is a crucial aspect of customization and tailoring the design to meet requirements like rigid-flex PCB manufacturers introduces unique cost considerations.

Strategies for Cost-Effective Rigid-Flex PCB Manufacturing

To enhance the cost-effectiveness in rigid-flex PCB manufacturing, several strategies can be employed that focus on optimizing various aspects of the design and manufacturing process to achieve cost savings without compromising performance.

- Stacking

One of the common strategies to save on flexible PCB costs is to stack various parts on top of each other which maximizes space efficiency, providing a more workable area for testing and other processes. This helps the manufacturers achieve cost savings in material usage and streamline the manufacturing process such as in that of rigid-flex PCB suppliers.

- Reduce PCB Dimensions to Save Materials

Rigid and flexible PCBs designed in smaller sizes contribute to significant material savings. The smaller-sized boards reduce the amount of copper laminates needed which directly impacts material costs due to compact designs as that of rigid-flex PCB manufacturers.

- Considerations on Mounting

The incorporation of connectors, feet, or displays in rigid-flex PCBs introduces strategic choices in mounting components that impact the overall cost structure. By evaluating different mounting options based on the specific requirements of the application, the design for both functionality and cost efficiency can be optimized.

- Incorporation of Fewer Parts

While it may not be possible to reduce the number of components used in PCBs, manufacturers can optimize the yield by using single-sided boards that can improve yield by reducing the number of parts required. This approach contributes to cost savings in terms of material usage and handling.

- Optimize Design to Achieve Simple PCB Assembly

The assembly process for rigid-flex PCBs can be complex during soldering which can be simplified by optimizing the design for easier handling. This may involve strategic decisions in the layout and configuration of components, ensuring a smoother assembly process. Streamlining assembly requirements not only reduces manufacturing time but also contributes to overall cost savings.

- Avoid Conformal Coating in PCBA if Possible

To protect PCBs from damage, a protective coating is typically applied which adds to the overall cost of manufacturing. Removing these protective coats can offer a cost-effective solution. While this approach may limit the lifespan of the PCBs and their application scenarios, it presents a viable option for cases where extended durability is not a critical requirement.

- Use More Equipment to Avoid Human Errors

Human errors during the manufacturing process can significantly impact costs. Manufacturers can implement stringent quality control measures to minimize errors. Thorough supervision of the manufacturing processes, especially those prone to human error, contributes to cost reduction by avoiding rework and material wastage.

- Implement Advanced Testing

Testing is a crucial phase in PCB manufacturing which can incur additional costs. Manufacturers can invest in efficient testing processes to minimize associated costs while maintaining high-quality standards. Implementing advanced testing technologies and methodologies ensures that most manufacturing progress is error-free, reducing the need for costly rework and adjustments.

- Use Stiffeners to Achieve Overall Thickness

Achieving the desired thickness in a rigid flex PCB can be challenging. Manufacturers can leverage rigid board laminates to attain the required overall thickness while maintaining flexibility which provides structural integrity, allowing for the creation of thicker boards without compromising on flexibility. Strategic use of stiffeners addresses specific design requirements, contributing to cost-effective solutions.

- Limit Controlled Impedance Requirements

Controlled impedance requirements in rigid PCBs can limit design flexibility and introduce complexity. Limiting controlled impedance requirements allows for simpler design processes, contributing to cost efficiency without sacrificing performance.

- Specialized Processing

Manufacturers can employ specialized processing techniques to ensure consistent quality across flex rigid PCB production such as that of rigid-flex PCB supplier. Specialized processes, developed through experience and expertise, contribute to uniformity in manufacturing outcomes and reduce the likelihood of defects and errors, ultimately leading to cost savings by minimizing the need for rework and adjustments.

- Smart Characteristics

Rigid PCBs often have limitations in terms of flexibility, with a typical restriction of flexing by no more than 1mm. Advanced materials and manufacturing processes enable the creation of flexible PCBs with enhanced flexibility, expanding the application possibilities. While incorporating smart characteristics may introduce additional costs, the resulting performance benefits can justify the investment.

Conclusion

To summarize, understanding the cost components of rigid-flex PCB manufacturing requires a thorough examination of design requirements, material properties, manufacturing methods, and strategic concerns. Manufacturers and stakeholders need to take a holistic approach, combining technical expertise with innovative ideas to produce cost-effective and high-performance rigid-flex PCBs customized to the needs of various applications.