Understanding Jake Brake Switches: Why and How They’re Used in Heavy Duty Diesel Engines

Jake brakes, also known as engine brakes or compression release engine brakes, are essential components in heavy-duty diesel engines used in the trucking, tractor, and construction industries. Jake brake switches allow drivers to activate and deactivate these engine brakes to provide enhanced control and safety when traveling downhill or slowing down with heavy loads. With the simple flick of a switch, drivers can harness the power of their engine to complement standard wheel braking, preventing dangerous brake overheating and failure.

Experience enhanced performance with a Diesel Tune. Optimize your vehicle’s power and efficiency through expert tuning, unlocking a new level of driving satisfaction and fuel economy.

In this article, we will explore what exactly Jake brakes are, why they are vital for managing the sheer momentum of loaded heavy vehicles, and how Jake brake switches allow drivers to safely and effectively utilize these brakes on steep grades and under heavy loads. When barreling down a highway at 60 mph or navigating a construction site laden with 30 tons of earth, drivers need every tool at their disposal to maintain control. Understanding proper Jake brake use provides that critical ability to curb momentum using the engine itself, delivering indispensable braking redundancy.

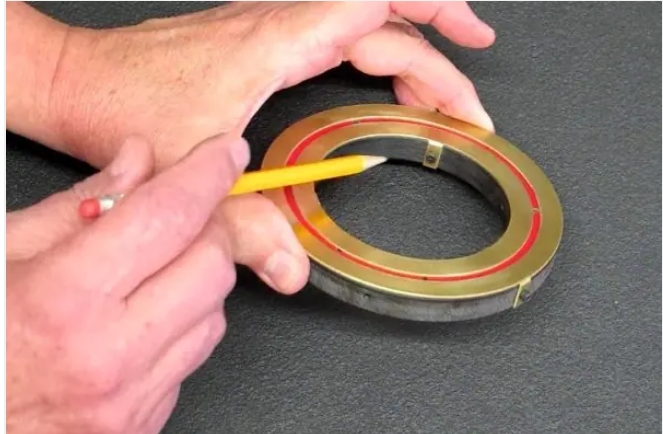

What is a Jake Brake?

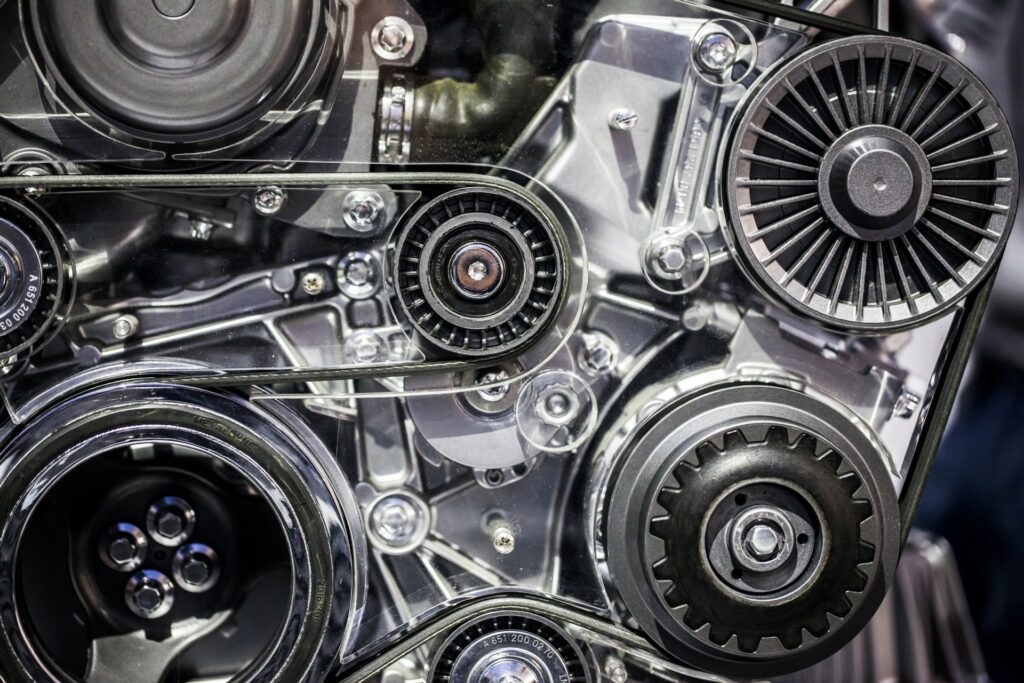

A Jake brake is a special braking mechanism that provides retardation power by modifying the engine’s compression stroke. When activated, the jake brake switch triggers the brake on the exhaust stroke of the piston, releasing the compressed air and preventing the energy from being returned to the crankshaft. This provides resistance against the momentum of the vehicle, helping to slow it down without solely relying on wheel brakes.

Jake brakes are commonly used in tandem with traditional wheel brakes to provide enhanced braking power, especially when traveling downhill or slowing with a loaded trailer or machinery. Using just the wheel brakes for prolonged periods can cause dangerous overheating and brake fade. The Jake brake reduces wear and tear on service brakes.

Why are Jake Brakes Important in Heavy Vehicles?

Jake brakes play a crucial role in large trucks, tractors, dump trucks, and other heavy machinery for several key reasons:

- Prevent brake overheating and failure when traveling long declines

- Increase stopping power and control with heavy loads

- Reduce wear and maintenance costs for service brakes

- Provide engine braking assistance to wheel brakes

- Improve safety and prevent runaway vehicles on steep grades

Without Jake brakes complementing wheel brakes, heavy diesel trucks would face much greater risks of brake failure, runaway trucks, and loss of control. Jake brakes fill a critical role in heavy vehicle braking systems.

The Pros of Jake Brakes for Heavy-Duty Vehicles

While all diesel vehicles can benefit from Jake brakes, they are especially critical in certain heavy-duty applications:

Large Semi-Truck Tractor Trailers

- Loaded tractor-trailers can weigh 80,000 lbs. and gain huge momentum

- Jake brakes are essential for maintaining control at high speeds

Dump Trucks

- Dump trucks haul extremely heavy loads downhill after unloading

- Jake brakes allow drivers to manage momentum when empty

Mining/Construction Equipment

- Vehicles like excavators operate in hilly areas

- Jake brakes provide braking power without wearing service brakes

Fire Trucks and other Emergency Vehicles

- Rapid deceleration is required even at high speeds

- Jake brakes allow faster braking for emergencies

In all these cases, Jake brakes provide substantial benefits:

- Prevent brake overheating and failure under heavy loads

- Allow trucks to maintain speed control in mountainous regions

- Reduce wear-and-tear on standard brake components

- Deliver peace of mind to operators hauling massive weight

For any vehicle routine exposed to steep inclines and heavy payloads, the compression release retardation of a Jake brake delivers invaluable control and safety. Their performance under demanding conditions makes them virtually indispensable for heavy-duty diesel vehicles.

Operating Jake Brake Switches

The Jake brake switch allows drivers to activate the Jake brake compression release in the engine. Here is how to properly operate Jake brake switches:

- Locate the switch on the dash – often a two-position or three-position rocker switch

- Before a decline, switch the Jake brake on to activate engine braking and retardation

- Modulate retardation strength with different switch positions

- To increase power on inclines, switch off to deactivate the compression release

- Switch off when Jake braking is no longer needed

Newer digital switches allow even more precise control over the extent of brake retardation. Proper use of the Jake brake switch prevents over-braking and keeps the vehicle safely under control.

Best Practices for Jake Brake Use

Operators should follow these best practices when using Jake brakes:

- Only use for prolonged braking requirements – not common stopping

- Do not use at low RPMs to avoid engine damage

- Adjust retardation level appropriately for the grade and vehicle weight

- Allow engine to warm up before extended Jake braking

- Avoid rapid on/off cycling of the brake to prevent wear

- Shift to lower gears when Jake braking for maximum effectiveness

- Combine Jake brake with wheel brakes for optimal braking capacity

Following these guidelines will allow drivers to maximize the benefits of Jake engine brakes and operate vehicles safely.

Whether hauling cargo across country, hauling heavy machinery up slopes, or navigating tight corners on a construction site, heavy diesel vehicles require specialized braking power. Jake brakes fulfill an essential role in enhancing safety and control when standard wheel brakes alone can’t withstand the load and momentum. With the simple flick of a Jake brake switch, drivers of semi-trucks, dump trucks, tractors, and other heavy vehicles can retard momentum using the engine itself – preventing dangerous overheating of brake pads and drums.

Mastering proper use of Jake brake switches provides heavy vehicle operators with an added dimension of control. The compression release of the Jake brake working in concert with wheel braking results in tremendous stopping capacity with massive loads. This combats the risks of brake failure and runaway vehicles inherent in mountain driving or construction sites. As engine braking technology continues advancing, Jake brakes are becoming even more fine-tuned and responsive to driver input through the switch.

From hauling excavators up a winding slope to controlling the speed of a loaded tractor-trailer barreling down a 6% grade highway, Jake brake switches empower safe descent. While advances in wheel braking fluids and materials continue, the relief provided by supplementary engine braking remains invaluable. Wise heavy vehicle owners will continue outfitting their rigs with Jake brakes and training drivers in their expert use. Because at the end of a long descent, there is no substitute for the safety and control provided by compression-release engine retarders.